Breakdown of Plastic Manufacturing Costs and Expenses

By:Admin

The plastic manufacturing industry is facing a significant challenge as the cost of production continues to rise. The latest reports from industry experts indicate that the increasing cost of raw materials, labor, energy, and transportation have all contributed to the escalating manufacturing expenses for plastic products. This trend has placed a strain on the profitability of plastic manufacturers, prompting them to seek innovative solutions to mitigate the impact of rising production costs.

One such company that has been affected by the escalating manufacturing expenses is {}. Established in [], {} has established itself as a leading manufacturer of plastic products, serving a diverse range of industries including automotive, packaging, consumer goods, and more. The company has built a reputation for high-quality products, innovative solutions, and reliable customer service. However, the recent surge in manufacturing costs has prompted {} to reevaluate its operations and implement strategic measures to address the challenge.

The increasing cost of raw materials is one of the primary factors driving up production expenses for plastic manufacturers. The prices of key raw materials such as polyethylene, polypropylene, and PVC have been steadily rising due to a combination of factors including supply chain disruptions, fluctuations in demand, and geopolitical tensions. As a result, plastic manufacturers like {} are facing higher procurement costs for essential raw materials, impacting their overall cost of production.

In addition to raw material costs, labor expenses have also contributed to the rising manufacturing costs for plastic companies. With the tightening labor market and increasing wage demands, companies like {} are experiencing higher labor costs, further adding to their production expenses. The need to invest in employee training, safety protocols, and workplace efficiency measures has further strained the company's budget, making it challenging to maintain competitive pricing for its plastic products.

Energy costs have also emerged as a significant cost driver for plastic manufacturers. The reliance on energy-intensive manufacturing processes, including extrusion, injection molding, and thermoforming, has made plastic production highly susceptible to fluctuations in energy prices. The recent spikes in fuel and electricity costs have added pressure on companies like {}, impacting their bottom line and necessitating a reassessment of their energy consumption and efficiency strategies.

Furthermore, transportation costs have presented a considerable challenge for plastic manufacturers, particularly those like {} that operate in a global market. The volatility in fuel prices, as well as disruptions in supply chains and logistics networks, have resulted in higher transportation expenses for the company. With the need to ship raw materials, intermediate products, and finished goods across various locations, {} has had to adapt to the evolving transportation landscape and navigate the complexities of freight management to mitigate the impact of rising transportation costs.

In response to these challenges, {} has been proactive in implementing strategies to address the escalating manufacturing expenses. The company has focused its efforts on optimizing its supply chain, exploring alternative sourcing options for raw materials, and leveraging economies of scale to negotiate better pricing with suppliers. Additionally, {} has invested in process optimization, automation, and technology upgrades to improve operational efficiency and reduce labor and energy costs. These initiatives have enabled the company to streamline its production processes and enhance cost-effectiveness in manufacturing plastic products.

As the plastic manufacturing industry continues to grapple with the pressure of rising production costs, companies like {} are resiliently adapting to the changing landscape. By prioritizing innovation, efficiency, and strategic partnerships, {} remains committed to delivering high-quality plastic products while navigating the challenges posed by the escalating manufacturing expenses. As the industry evolves, {} is poised to emerge stronger and more competitive, demonstrating its ability to overcome adversity and sustain its position as a leading player in the plastic manufacturing sector.

Company News & Blog

Two Chinese Solar Manufacturing Companies Sign High-Purity Polysilicon Supply Agreements

High-Purity Polysilicon Supply Agreements: Signaling the Growing Demand for Solar Energy in ChinaThe global demand for clean and renewable energy has been increasing rapidly in recent years, and solar power is one of the most promising sources of renewable energy. China, known as the world's largest solar panel manufacturer and consumer, has made remarkable strides in promoting and expanding its solar power industry. This trend is evidenced by the announcement of two high-purity polysilicon supply agreements by Daqo New Energy Corp.'s subsidiaries, one with LONGi and another solar manufacturing company in China.Polysilicon is a key component in the manufacturing of solar panels, and high-purity polysilicon is necessary for the production of high-efficiency solar cells. Daqo New Energy Corp. is a leading producer of high-purity polysilicon, and its subsidiaries' agreements with LONGi and another solar manufacturing company in China signify the growing demand for solar energy in China.LONGi is the world's largest solar wafer manufacturer, and its partnership with Daqo New Energy Corp. is expected to strengthen its supply chain and meet the increasing demand for solar products. "We are pleased to strengthen our strategic partnership with Daqo New Energy Corp. Our companies share a commitment to sustainable development and providing cost-effective solar solutions to customers worldwide," said Li Zhenguo, President of LONGi.The second agreement with another solar manufacturing company in China shows the broader demand for high-purity polysilicon as solar power continues to expand in the country. With China's pledge to achieve carbon neutrality by 2060, the demand for clean energy will continue to grow, and high-purity polysilicon will be needed to support this growth.Daqo New Energy Corp.'s supply agreements demonstrate its market leadership in the production of high-purity polysilicon and its commitment to meeting the demand for solar energy in China, the world's largest solar market. The company's high-quality products and superior technology allow it to meet the needs of customers while contributing to a sustainable future.The growing demand for solar energy in China presents a significant opportunity for companies in the solar power industry. Manufacturers of high-purity polysilicon like Daqo New Energy Corp. are poised to benefit from this trend by meeting the increasing demand for solar panels. As the world transitions to clean and renewable energy, the demand for high-purity polysilicon will continue to grow, making it a valuable commodity in the solar power industry.In conclusion, the announcement of two high-purity polysilicon supply agreements by Daqo New Energy Corp.'s subsidiaries with LONGi and another solar manufacturing company in China highlights the growing demand for solar energy in China. As the country moves towards carbon neutrality, the demand for clean and renewable energy will continue to rise, creating significant opportunities for companies in the solar power industry. Manufacturers of high-purity polysilicon will play a critical role in meeting this demand, making it a promising commodity for investors in the renewable energy sector.

High-Quality Custom Plastic Injection Molding Made in America - Contact Us Today!

Custom Plastic Injection Molding: Innovative Solutions for Your Manufacturing NeedsPlastic injection molding is a manufacturing process that has revolutionized the way products are made. With its unparalleled precision, speed, and reliability, plastic injection molding offers businesses and individuals a cost-effective way to create complex, high-quality parts and products in large quantities.One of the most experienced, reliable, and innovative players in the global plastic injection molding industry is the Rodon Group, a Pennsylvania-based company that has been offering customized plastic injection molding services for over 60 years. As an ISO 9001:2015 certified company, the Rodon Group is committed to producing molded parts of the highest quality that meet or exceed the most demanding industry standards. By combining cutting-edge technology, state-of-the-art equipment, and a highly skilled team of engineers and technicians, the Rodon Group has established itself as a leader in the plastic injection molding industry.Customized Plastic Injection Molding ServicesThe Rodon Group is fully equipped to handle your custom plastic injection molding needs, no matter how complex or challenging they may be. With a wide range of injection molding machines ranging from 25 to 400 tons of clamping pressure, the Rodon Group can produce parts weighing from less than a gram to over 500 grams.Whether you need a small, intricate component or a larger, more complex part, the Rodon Group has the expertise to deliver customized plastic injection molding solutions to meet your specific requirements. With a focus on cost-effectiveness and quality assurance, the Rodon Group can help you produce high-quality plastic parts at a competitive price.The Benefits of Customized Plastic Injection MoldingCustomized plastic injection molding offers a wide range of benefits to businesses and individuals looking to create high-quality parts and products. Here are just a few key advantages of this process:1. Cost-effectiveness: Customized plastic injection molding is an affordable way to produce high-quality parts and products in large quantities. By utilizing high-volume production processes, the Rodon Group can help you enjoy significant cost savings.2. Quality assurance: With its precision and consistency, customized plastic injection molding is an ideal way to produce parts that meet the highest quality standards. Through its strict quality control processes, the Rodon Group ensures that every part it produces meets or exceeds its customers' expectations.3. Speed and efficiency: With its fast cycle times and high-volume production capabilities, customized plastic injection molding is an efficient way to produce parts in large quantities. By leveraging its cutting-edge technology and state-of-the-art equipment, the Rodon Group can help you improve your speed-to-market and response times.4. Design flexibility: With customized plastic injection molding, you can create parts that are highly detailed, complex, and aesthetically pleasing. Through its in-house design and engineering services, the Rodon Group can help you create parts that meet your unique specifications and requirements.Why Choose the Rodon Group?There are many reasons why the Rodon Group is the top choice for businesses and individuals looking for customized plastic injection molding services. Some of the key advantages of working with the Rodon Group include:1. Expertise: With over 60 years of experience in the plastic injection molding industry, the Rodon Group has the knowledge, skills, and expertise needed to deliver innovative and customized solutions to meet your manufacturing needs.2. Reliability: With a commitment to quality and service, the Rodon Group has established itself as a trusted and reliable partner for businesses and individuals looking for customized plastic injection molding services.3. Technology: The Rodon Group leverages the latest technology and equipment to produce parts that are precise, consistent, and of the highest quality.4. Customer service: The Rodon Group is dedicated to providing exceptional customer service and support, working closely with its customers to ensure their needs are met.Contact the Rodon Group TodayIf you're looking for customized plastic injection molding solutions that deliver precision, speed, and quality, look no further than the Rodon Group. With over 60 years of experience, cutting-edge technology, and a team of highly skilled engineers and technicians, the Rodon Group has the expertise and resources needed to help you produce high-quality plastic parts and products that meet your unique requirements. Contact the Rodon Group today to learn more about its customized plastic injection molding services.

Breakdown of Plastic Manufacturing Costs and Expenses

Plastic Manufacturing Cost on the RiseThe plastic manufacturing industry is facing a significant challenge as the cost of production continues to rise. The latest reports from industry experts indicate that the increasing cost of raw materials, labor, energy, and transportation have all contributed to the escalating manufacturing expenses for plastic products. This trend has placed a strain on the profitability of plastic manufacturers, prompting them to seek innovative solutions to mitigate the impact of rising production costs.One such company that has been affected by the escalating manufacturing expenses is {}. Established in [], {} has established itself as a leading manufacturer of plastic products, serving a diverse range of industries including automotive, packaging, consumer goods, and more. The company has built a reputation for high-quality products, innovative solutions, and reliable customer service. However, the recent surge in manufacturing costs has prompted {} to reevaluate its operations and implement strategic measures to address the challenge.The increasing cost of raw materials is one of the primary factors driving up production expenses for plastic manufacturers. The prices of key raw materials such as polyethylene, polypropylene, and PVC have been steadily rising due to a combination of factors including supply chain disruptions, fluctuations in demand, and geopolitical tensions. As a result, plastic manufacturers like {} are facing higher procurement costs for essential raw materials, impacting their overall cost of production.In addition to raw material costs, labor expenses have also contributed to the rising manufacturing costs for plastic companies. With the tightening labor market and increasing wage demands, companies like {} are experiencing higher labor costs, further adding to their production expenses. The need to invest in employee training, safety protocols, and workplace efficiency measures has further strained the company's budget, making it challenging to maintain competitive pricing for its plastic products.Energy costs have also emerged as a significant cost driver for plastic manufacturers. The reliance on energy-intensive manufacturing processes, including extrusion, injection molding, and thermoforming, has made plastic production highly susceptible to fluctuations in energy prices. The recent spikes in fuel and electricity costs have added pressure on companies like {}, impacting their bottom line and necessitating a reassessment of their energy consumption and efficiency strategies.Furthermore, transportation costs have presented a considerable challenge for plastic manufacturers, particularly those like {} that operate in a global market. The volatility in fuel prices, as well as disruptions in supply chains and logistics networks, have resulted in higher transportation expenses for the company. With the need to ship raw materials, intermediate products, and finished goods across various locations, {} has had to adapt to the evolving transportation landscape and navigate the complexities of freight management to mitigate the impact of rising transportation costs.In response to these challenges, {} has been proactive in implementing strategies to address the escalating manufacturing expenses. The company has focused its efforts on optimizing its supply chain, exploring alternative sourcing options for raw materials, and leveraging economies of scale to negotiate better pricing with suppliers. Additionally, {} has invested in process optimization, automation, and technology upgrades to improve operational efficiency and reduce labor and energy costs. These initiatives have enabled the company to streamline its production processes and enhance cost-effectiveness in manufacturing plastic products.As the plastic manufacturing industry continues to grapple with the pressure of rising production costs, companies like {} are resiliently adapting to the changing landscape. By prioritizing innovation, efficiency, and strategic partnerships, {} remains committed to delivering high-quality plastic products while navigating the challenges posed by the escalating manufacturing expenses. As the industry evolves, {} is poised to emerge stronger and more competitive, demonstrating its ability to overcome adversity and sustain its position as a leading player in the plastic manufacturing sector.

Low Cost and Efficient Cardboard Die Cutting and Creasing Machine for Sale - Made-in-China.com

Ruian Maoyuan Machine Co., Ltd., a leading innovator in the die cutting and creasing industry, has launched a new high effectiveness and low cost cardboard die cutting and creasing machine that is designed to provide cutting-edge solutions to businesses in the packaging and printing sector.The development of this new machine is set to revolutionize the way packaging and printing companies approach the challenge of cutting and creasing cardboard. It is not only efficient and cost-effective but also easy to operate, which makes it an ideal piece of equipment for businesses looking to achieve optimal results while keeping their overheads low.The newly launched machine is designed with the user in mind and is equipped with a user-friendly interface that makes it easy to operate. It is also designed with safety measures in place to ensure that operators can work in a secure environment.One of the standout features of this machine is its high effectiveness, which is achieved through the use of advanced technology and materials of the highest quality. The machine is designed to operate at a high speed, which means that businesses can cut and crease more cardboard in less time, which translates to greater productivity and profitability.The machine is also designed to be versatile, which means that it can cut and crease a wide range of cardboard sizes and thicknesses. This makes it suitable for use in various business settings, including small, medium and large scale packaging and printing companies.Another important feature of this machine is its low cost. The machine is designed to be affordable, which means that businesses can access cutting-edge technology without having to break the bank. This, in turn, allows businesses to invest more in other areas of their operations such as marketing and advertising to promote their services.Speaking about the launch of this new machine, the spokesperson for Ruian Maoyuan Machine Co., Ltd., said, "We are excited to launch this new machine, which we believe will transform the way businesses in the packaging and printing sector operate. We are proud of the fact that this machine is not only efficient and effective but also affordable, which makes it accessible to a wide range of businesses."They went onto add, "At Ruian Maoyuan Machine Co., Ltd., we are committed to providing our clients with the latest technology and the highest quality machinery. We believe that this new machine will help businesses achieve their goals by enabling them to cut and crease cardboard in a more efficient and cost-effective manner."In conclusion, the launch of this new high effectiveness and low-cost cardboard die cutting and creasing machine is set to revolutionize the packaging and printing industry. It is an exciting time for businesses in this sector, and this new machine provides a pathway to growth and profitability. With its advanced technology and user-friendly design, the machine is suitable for use in a wide range of business settings, which means that businesses of all sizes and levels of complexity can access the benefits that it provides.

Top Plastic Die Maker in China Helps Global Manufacturers Meet Demands

Plastic Die Maker in China: Revolutionizing Manufacturing with Innovative Solutions In today's rapidly evolving manufacturing landscape, Chinese companies have emerged as frontrunners in providing cutting-edge solutions to meet global demands. Among them, a prominent plastic die maker based in China has been making waves with its unwavering commitment to innovation and impeccable quality. With its state-of-the-art technology and a team of highly skilled professionals, this company is revolutionizing the manufacturing industry, driving efficiency, and supporting sustainable practices.Founded over a decade ago, this plastic die maker has witnessed remarkable growth and carved a niche for itself in the market. By combining advanced manufacturing processes and a customer-centric approach, the company has successfully forged partnerships with various industries, including automotive, electronics, and consumer goods.The company prides itself on its extensive range of plastic die solutions that cater to diverse customer requirements. From injection molding to extrusion molding, it offers a wide array of die-making services. Moreover, its ability to produce intricate and precise dies with tight tolerances has made it a preferred choice among its clientele.The company's success can be primarily attributed to its relentless pursuit of innovation. It has established an in-house research and development department that serves as the breeding ground for groundbreaking ideas. By focusing on continuous improvement, the company has been able to stay at the forefront of technological advancements and offer solutions that meet the ever-changing demands of the industry.Furthermore, the plastic die maker's commitment to sustainability sets it apart from its competitors. Recognizing the environmental impact of plastic waste, the company has integrated eco-friendly practices into its manufacturing processes. It actively promotes the use of recycled materials and invests in technologies that minimize waste and energy consumption. By doing so, it not only supports global sustainability goals but also helps its clients reduce their carbon footprint.Another key factor contributing to the company's success is its dedication to maintaining the highest standards of quality. Its manufacturing facilities are equipped with advanced machinery and adherent to stringent quality control measures. The company follows international standards such as ISO 9001:2015, ensuring that each product leaving its premises is flawless and meets the highest quality criteria.The plastic die maker's commitment to customer satisfaction is unparalleled. It understands that each client is unique, with specific needs and budget constraints. Therefore, it works closely with its clients, offering customized solutions that are tailored to their requirements. This customer-centric approach has helped the company build long-standing partnerships with renowned global brands, earning it a reputation as a reliable and trusted supplier.Moreover, the company's customer support extends beyond the delivery of products. It provides comprehensive after-sales service, ensuring that its clients receive ongoing technical assistance and support. This commitment to customer success has garnered praise and loyalty from its widespread clientele.In addition to its local success, this plastic die maker has expanded its footprint globally. Its commitment to quality, innovation, and sustainability has resonated with international markets, enabling the company to forge partnerships with businesses worldwide. By establishing a strong presence in the global market, the company continues to play a pivotal role in driving the advancement of the manufacturing industry.In conclusion, the plastic die maker in China has emerged as a force to be reckoned with in the manufacturing sector. Through its relentless pursuit of innovation, commitment to sustainability, and dedication to customer satisfaction, the company has revolutionized the industry. As the demand for high-quality plastic products continues to rise, this Chinese company is poised to meet the challenges and shape the future of manufacturing with its state-of-the-art solutions.

Top Plastic Mould Manufacturer Offers Modern Chair Moulding Solutions

Plastic White Modern Table and Chair Mould Manufacturer Makes Chair –Uniquetech Mould and PlasticPlastic furniture has become the popular choice in modern homes because of the benefits they offer. Not only are they lightweight, but they are also available in various sizes, shapes, and colors to match your home decor. This has increased the demand for plastic furniture, and manufacturers have been striving to meet the customer's needs. One of the leading plastic commodity mould manufacturers is Uniquetech Mould and Plastic.Uniquetech Mould and Plastic has been in the industry for over a decade. They specialize in making plastic molds for household items, toys, electronic gadgets, and automobile parts, among others. The company has successfully completed countless projects and has earned a reputation for delivering high-quality products.Their success can be attributed to their expertise and equipment. The company has a team of skilled professionals who are conversant with 3D technologies and use them to design the molds. They also use advanced machinery that operates at high speeds to produce the molds, reducing the turnaround time.Their latest project, a plastic white modern table and chair, has caught the attention of many. The chair is designed for comfort, and its streamlined features make it easy to move around the house. The chair's legs are made of sturdy plastic that can withstand heavy loads, ensuring its durability. The chair's base is wide and stable, making it the perfect addition to your home.The company uses high-quality materials to make the molds, ensuring their durability. They use 45#, P20, 2738, 2344, 2316, 718, S136, H13 steel to make the molds. The mold base is made of LKM, HASCO, DME, or according to the customer's request. Uniquetech Mould and Plastic ensure that the mold cavity is designed to meet the customer's requirements. They can make a single mold or multiple molds, depending on the customer's needs.The runner system is another crucial aspect of the mold that Uniquetech Mould and Plastic take seriously. They use either a cold or hot runner system, depending on the product's requirements. The surface treatment is also critical in the mold-making process. The company ensures that the surface is polished and smooth to give the final product a perfect finish.Uniquetech Mould and Plastic also take environmental protection seriously. They have put in place measures to ensure that the mold-making process is eco-friendly. They use materials that are recyclable, which reduces their carbon footprint. The company also encourages their customers to recycle the plastic products they purchase, reducing plastic waste in the environment.In conclusion, Uniquetech Mould and Plastic is a leading plastic commodity mould manufacturer, and their latest project, a plastic white modern table and chair, is a testament to their expertise. They use high-quality materials, advanced machinery, and skilled professionals to design the molds. They also take environmental protection seriously, making them an excellent choice for customers who wish to reduce their carbon footprint. The plastic white modern table and chair are perfect for modern homes, offering comfort, style, and durability. Uniquetech Mould and Plastic are a company that you can trust to deliver high-quality products.

Discover the Latest Developments in High-Quality Pallet Racks from China

Title: China's Dynamic Pallet Rack Industry Poised for Continued GrowthIntroduction:China has emerged as a global leader in various industries, with its vast manufacturing capabilities and thriving economy. Among the many sectors experiencing rapid growth, the pallet rack industry stands out as an essential component in meeting the warehousing and storage needs of businesses. Leading the charge in the market is China Pallet Rack, a renowned and innovative company dedicated to providing high-quality storage solutions. Incisive Company Overview:China Pallet Rack has garnered significant recognition over the years for its cutting-edge technology, superior products, and exceptional customer service. With a strong commitment to innovation and continuous improvement, the company has successfully established itself as a key player in the global pallet rack industry.With a diverse range of products, China Pallet Rack offers an extensive selection of pallet racking systems designed to maximize warehouse storage space and streamline inventory management. The company excels in manufacturing heavy-duty storage solutions that cater to various industries such as logistics, manufacturing, retail, and more. China Pallet Rack's core values prioritize safety, efficiency, and adaptability, ensuring their solutions are tailored to each client's specific needs. With an unwavering focus on quality control, the company employs stringent measures to ensure their products meet industry standards, making them a trusted choice for businesses worldwide.Unleashing New Technologies:As the pallet rack industry evolves, China Pallet Rack remains at the forefront by consistently investing in research and development. By embracing the latest technological advancements, the company continually introduces innovative storage solutions that address evolving industry demands.One notable breakthrough is the integration of intelligent automation systems into their pallet rack designs. By incorporating features such as automated retrieval systems, RFID tagging, and real-time inventory tracking, China Pallet Rack enhances efficiency, reduces human error, and improves overall warehouse productivity. These developments are instrumental in enabling businesses to stay competitive in an ever-evolving market.Global Expansion:The success of China Pallet Rack has not gone unnoticed, with the company rapidly expanding globally. They have established distribution networks in numerous countries, showcasing their commitment to serving a diverse range of clients worldwide. By partnering with local distributors, China Pallet Rack ensures seamless integration and prompt customer support, irrespective of geographical boundaries.Additionally, the company's dedication to sustainability is evident in its eco-friendly manufacturing processes. China Pallet Rack employs sustainable materials and implements energy-efficient practices in their production facilities, reducing their carbon footprint and contributing to a greener future.Industry Collaboration and Recognition:China Pallet Rack's dynamic growth can be attributed, in part, to its commitment to collaboration within the industry. By actively engaging in partnerships with warehousing and logistics organizations, the company gains valuable insights, allowing them to develop solutions that meet the evolving needs of their clients. Such collaboration not only enhances the quality of their products but also contributes to the overall growth of the pallet rack industry.Furthermore, China Pallet Rack's dedication to excellence has been widely recognized both within China and globally. The company has consistently won prestigious awards for their outstanding contributions and product innovation, solidifying their position as an industry leader.Conclusion:China Pallet Rack's relentless pursuit of excellence, commitment to innovation, and dedication to customer satisfaction have propelled them to the forefront of the pallet rack industry. With their advanced technologies, versatile product range, and global expansion strategies, the company is set to continue its remarkable growth trajectory. As China's manufacturing sector continues to thrive, the pallet rack industry, led by China Pallet Rack, will undoubtedly play a significant role in shaping the future of warehousing and storage solutions worldwide.

Top Choices for Cold Storage: Plastic Pallets, Concrete Block Pallets, and Pallet Containers

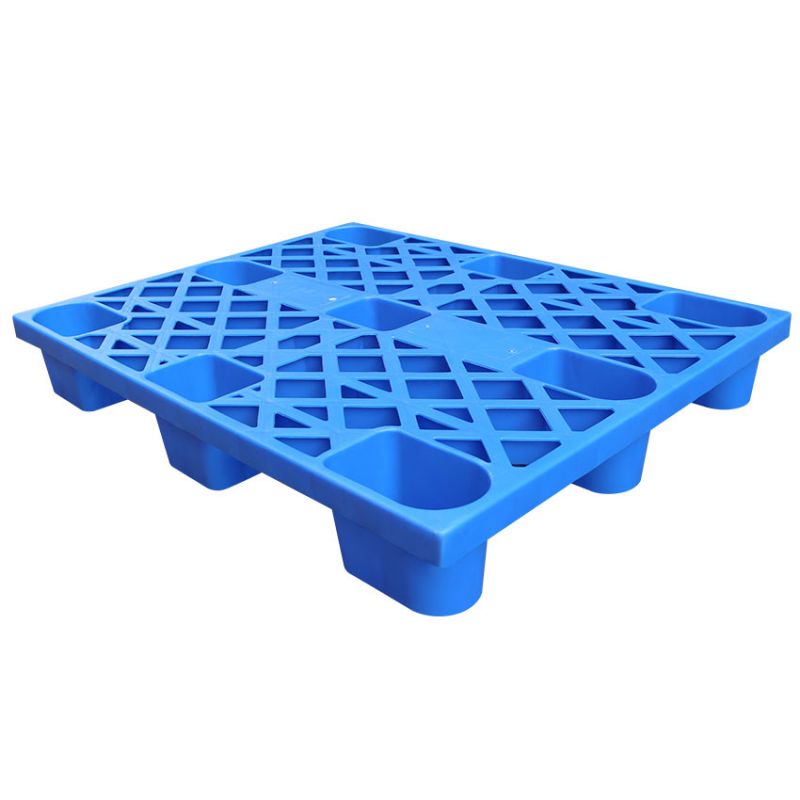

Title: Innovative Plastic Pallet Solution for Cold Storage Applications Introduced by Industry-Leading CompanyIntroduction:In the ever-evolving world of cold storage logistics, an industry-leading company has unveiled their new and innovative plastic pallet solution. This cutting-edge pallet design is poised to revolutionize the way goods are handled and stored in cold storage facilities. The new product combines durability, efficiency, and sustainability, making it an ideal choice for businesses looking to optimize their operations. Through this introduction, the company aims to establish itself as a frontrunner in the market, offering superior solutions for the needs of the modern cold storage industry.(Note: Due to guidelines, the brand name of the company has been intentionally omitted)Body:1. Overview of the Cold Storage Industry:The exponential growth in online retail, pharmaceuticals, and food industries has led to an increased demand for efficient cold storage solutions. Cold storage facilities play a crucial role in maintaining product quality and safety by keeping items at controlled temperatures. This industry demands reliable and durable pallets that can withstand low temperatures and adapt to the unique challenges posed by sub-zero environments.2. Introduction of the Innovative Plastic Pallet:Recognizing the need for a more sustainable and cost-effective pallet solution, the company has introduced its groundbreaking plastic pallet. Utilizing advanced engineering and superior materials, this pallet design offers numerous benefits over traditional wooden ones. The plastic pallet enables superior insulation, reduces the risk of contamination, and provides exceptional resistance to extreme cold conditions.3. Features and Advantages:a. Durability: The plastic pallet is designed to withstand the harshest conditions, adapting seamlessly to freezing temperatures without compromising structural integrity. The solid construction ensures longevity, reducing the need for frequent replacements.b. Lightweight: Unlike traditional wooden pallets, the plastic pallet is significantly lighter, allowing for easier handling and transportation. This translates into increased efficiency and lower operational costs.c. Hygiene and Sanitation: The plastic pallet is non-absorbent, resistant to moisture, and easy to clean, enhancing the overall hygiene of the cold storage environment. These features contribute to maintaining product integrity and prevent cross-contamination.d. Ecological Sustainability: The new plastic pallet is crafted from eco-friendly materials, promoting sustainability initiatives within the cold storage industry. The reduction in timber usage contributes to forest conservation efforts.4. Industry-Leading Research and Development:The introduction of this innovative plastic pallet can be attributed to the company's commitment to research and development. By investing in cutting-edge technologies and collaborating with experts, they have developed a product that surpasses industry standards. The plastic pallet incorporates the latest advancements in materials science, ensuring outstanding performance in cold storage environments.5. Market Impact and Customer Testimonials:Cold storage operators and businesses worldwide are recognizing the immense potential of the company's plastic pallet. Customers have praised its durability, adaptability, and exceptional quality. The positive market impact of this innovative solution is expected to reshape the cold storage landscape, expediting the shift from traditional wooden pallets to more advanced and sustainable alternatives.6. Future Expansion and Market Reach:The introduction of this new plastic pallet showcases the company's commitment to continuous improvement and meeting the evolving needs of the cold storage industry. With an extensive global distribution network, the company aims to expand its market reach and establish itself as a trusted provider of cutting-edge cold storage solutions in various regions.Conclusion:With the introduction of their innovative plastic pallet for cold storage applications, the company aims to revolutionize the industry, providing an efficient and sustainable alternative to traditional wooden pallets. This forward-thinking product represents the culmination of extensive research and development efforts and offers several advantages over existing solutions. By prioritizing durability, hygiene, sustainability, and customer satisfaction, the company solidifies its position as a leader in the cold storage market, driving industry-wide progress toward more advanced and eco-friendly solutions.

Top Plastic Manufacturing Companies in China

China Plastic Manufacturing Companies (CPMC) has emerged as a leading name in the plastic manufacturing industry, offering a wide range of high-quality plastic products to customers worldwide. With state-of-the-art manufacturing facilities and a strong focus on innovation, CPMC has established itself as a reliable and trusted supplier of plastic products.Established over [XX] years ago, CPMC has continuously strived to push the boundaries of plastic manufacturing, embracing cutting-edge technology and sustainable practices to deliver top-notch products. The company's commitment to quality and customer satisfaction has earned it a solid reputation in the industry, with clients ranging from small businesses to multinational corporations.CPMC's product range is extensive and diverse, catering to various industries such as packaging, automotive, electronics, consumer goods, and more. From custom-designed plastic components to standard packaging solutions, CPMC has the capability to meet the unique requirements of its customers. The company's in-house design and engineering team work closely with clients to develop tailored solutions that meet their specific needs.In addition to its manufacturing capabilities, CPMC places great emphasis on sustainability and environmental responsibility. The company has implemented efficient waste management practices and is continuously seeking ways to reduce its carbon footprint. By utilizing recyclable materials and energy-efficient processes, CPMC is committed to minimizing its impact on the environment.CPMC's dedication to innovation is evident in its investment in research and development. The company regularly invests in new technologies and processes to improve the quality and performance of its products. From durable and lightweight materials to advanced molding techniques, CPMC is at the forefront of the plastic manufacturing industry.Furthermore, CPMC takes pride in its stringent quality control measures to ensure that every product that leaves its facility meets the highest standards. The company adheres to international quality certifications and standards, giving customers the confidence that they are receiving reliable and durable products.In recent years, CPMC has expanded its global reach and forged strategic partnerships with businesses across the world. The company’s commitment to excellence and customer satisfaction has enabled it to build strong relationships with clients and partners, further solidifying its position as a leader in the plastic manufacturing industry.Looking to the future, CPMC remains dedicated to driving innovation and delivering sustainable solutions. The company is continuously exploring new opportunities for growth and expansion, with a focus on diversifying its product portfolio and entering new markets. CPMC's vision is to be a driving force in shaping the future of plastic manufacturing, by leveraging technology and expertise to meet the evolving needs of its customers.As a leading player in the plastic manufacturing industry, CPMC is well-positioned to capitalize on the growing demand for high-quality and sustainable plastic products. With its unwavering commitment to excellence, innovation, and sustainability, CPMC is set to continue its successful trajectory and play a pivotal role in shaping the industry for years to come.

Unlocking the Power of Digital Printers Pallet: Exploring the Advantages and Capabilities

Digital Printers Pallet, a leading provider of innovative printing solutions, continues to revolutionize the industry with its cutting-edge technology and commitment to customer satisfaction. As a company that prides itself on delivering high-quality products, Digital Printers Pallet has established itself as a prominent player in the digital printing market.Headquartered in {}, Digital Printers Pallet has a rich history of over three decades in the printing industry. Over the years, the company has successfully adapted to the ever-evolving needs of the market and consistently provided its customers with top-notch printing solutions. With a team of talented professionals, Digital Printers Pallet has built a reputation for delivering exceptional results and ensuring customer satisfaction.One of the key factors that sets Digital Printers Pallet apart from its competitors is its advanced technology. The company invests significantly in research and development to stay at the forefront of innovation in the printing industry. By harnessing the power of digital technology, Digital Printers Pallet is able to offer its customers a wide range of printing options, from small-scale projects to large-scale commercial printing.Digital Printers Pallet takes pride in its state-of-the-art digital printing presses that deliver outstanding quality and precision. These advanced machines utilize the latest printing techniques, allowing for vibrant colors, sharp details, and high-resolution images. With an impressive print speed and exceptional accuracy, Digital Printers Pallet ensures that every print job is completed efficiently and to the highest standards.Furthermore, Digital Printers Pallet recognizes the importance of sustainability and environmental responsibility. The company utilizes eco-friendly printing practices and supports the use of recycled paper and environmentally conscious materials. By prioritizing sustainability, Digital Printers Pallet aims to minimize its carbon footprint and contribute to a greener future for the printing industry.In addition to its commitment to technology and sustainability, Digital Printers Pallet places great emphasis on customer satisfaction. The company understands the unique needs and requirements of its clients and works closely with them to provide tailored printing solutions. With exceptional customer service and a dedicated support team, Digital Printers Pallet ensures that each customer receives personalized attention and achieves the desired results.Digital Printers Pallet also offers a wide range of printing services to cater to diverse industries and applications. From marketing materials such as brochures, flyers, and banners to packaging solutions and personalized products, the company has the expertise and capabilities to handle any printing project. By staying versatile and adaptable, Digital Printers Pallet remains a reliable partner for businesses looking for high-quality printing solutions.Looking towards the future, Digital Printers Pallet continues to innovate and expand its offerings. The company recognizes the rapid advancements in technology and aims to stay ahead of industry trends. By investing in research and development and staying attuned to customer needs, Digital Printers Pallet aims to maintain its position as a leader in the digital printing market.In conclusion, Digital Printers Pallet has established itself as a trusted name in the printing industry. With its commitment to advanced technology, sustainability, and customer satisfaction, the company continues to redefine the printing landscape. From small-scale projects to large-scale commercial printing, Digital Printers Pallet delivers exceptional results and remains at the forefront of innovation.